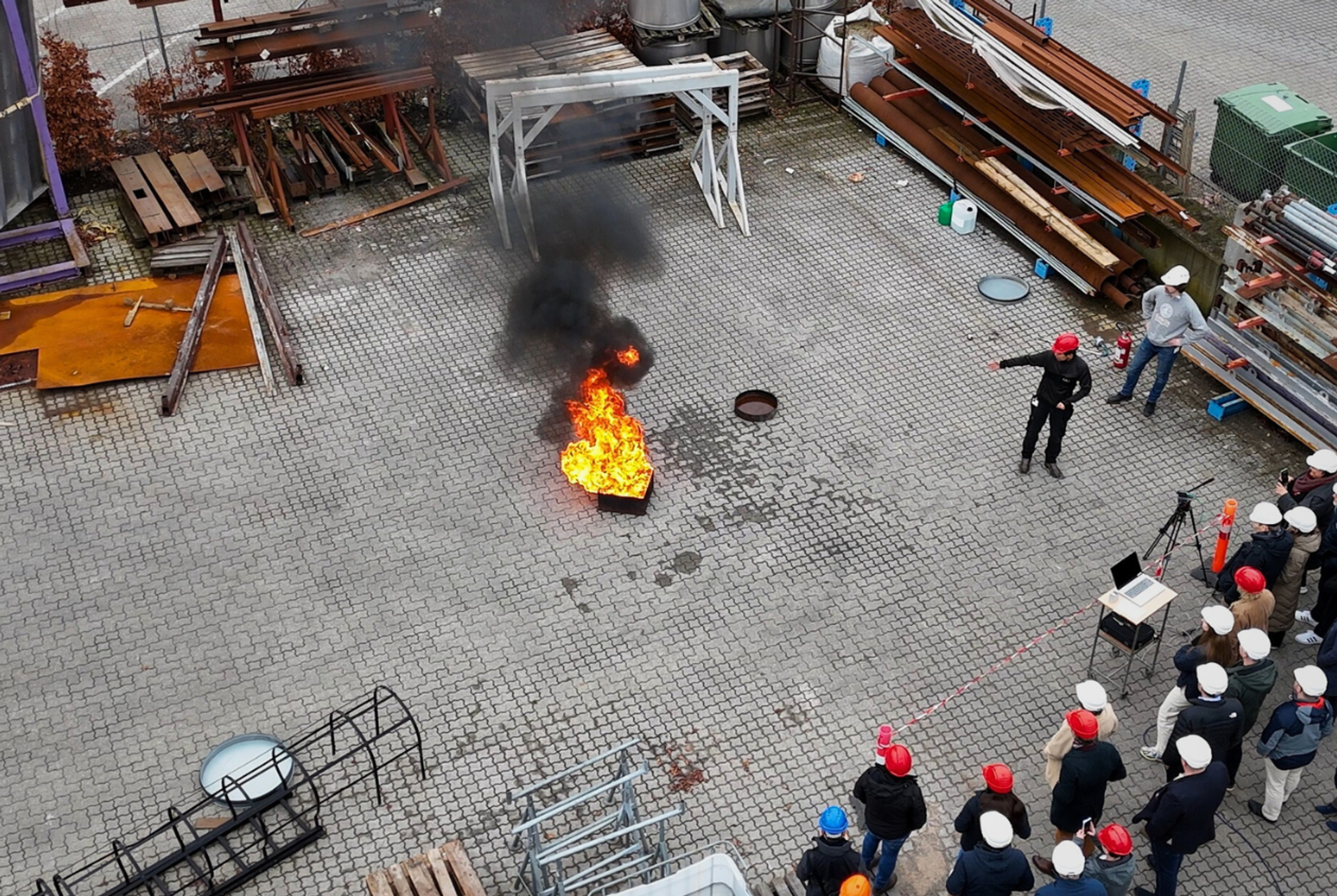

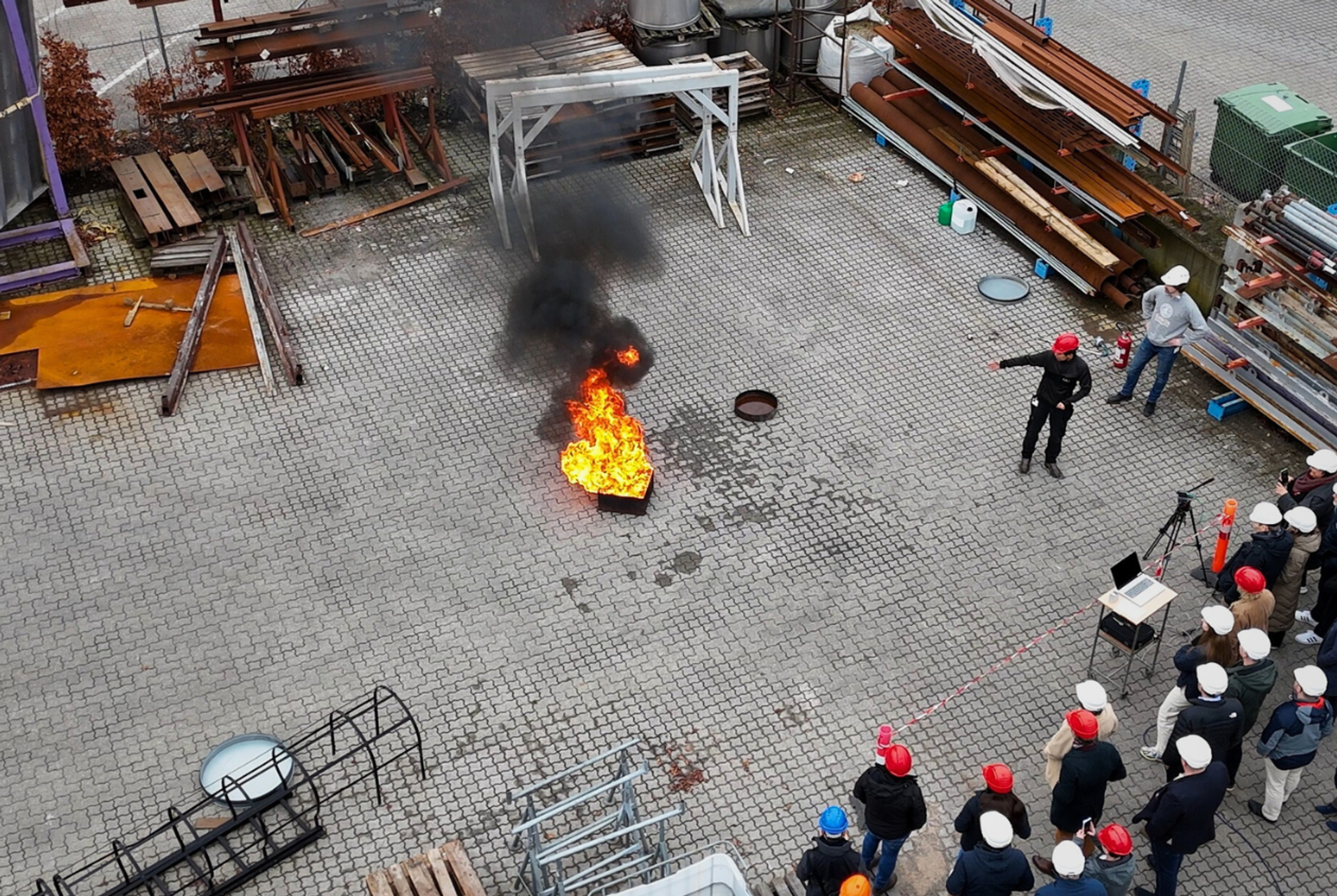

DBI: Free courses in H2 and PtX safety

Join a free course in Hydrogen- and Power-to-X safety with live demonstrations. All courses take place at DBI in Hvidovre, Greater Copenhagen, Denmark.

DBI’s role in GreenSkills4H2 project

DBI - The Danish Institute of Fire and Security Technology - is participating in the international project GreenSkills4H2 to contribute with expertise in fire, safety and risk management to the development of training programs for hydrogen technologies. As hydrogen becomes a central part of the green transition, DBI supports the project’s goal of preparing the workforce with the necessary skills to handle hydrogen safely and responsibly.

We offer 3 different courses concerning Power-to-X Safety, Introduction to Hydrogen Safety and Advanced Hydrogen Safety with different levels. All courses are free of charge. Read about the courses here or through the links below and sign up to gain new knowledge and improve your skills within hydrogen technologies.

- Power-to-X Safety: One-day course in Danish

- Introduction to Hydrogen Safety: One-day course in English

- Advanced Hydrogen Safety: Two-day course in English

About DBI -The Danish Institute of Fire and Security Technology

DBI is an independent GTS institute and high-tech research company specialising in fire safety and security. With over 100 years of experience, we offer accredited services in fire prevention, fire technology, and security, aimed at protecting lives and valuables. We work with Danish and international customers in the construction, energy and maritime sectors, ensuring compliance with legislation.

DBI acts as a Danish knowledge centre for fire safety for transport and renewable energy, with competence in risk analysis, testing and simulation. We help customers in energy and transport address new fire risks, improve current safety, and ensure fire safety does not hinder innovation, focusing on Power-to-X, wind energy and container ships. Our interdisciplinary expertise supports product development, consultancy and regulatory integration to meet technical, social and organisational safety needs.

We contribute to Danish and international standardisation, publish industry-related materials, and provide a wide range of fire safety and security courses through our dedicated course department, offering holistic solutions based on specialised knowledge and continuous development.

Latest news

DBI’s role in GreenSkills4H2 project

DBI - The Danish Institute of Fire and Security Technology - is participating in the international project GreenSkills4H2 to contribute with expertise in fire, safety and risk management to the development of training programs for hydrogen technologies. As hydrogen becomes a central part of the green transition, DBI supports the project’s goal of preparing the workforce with the necessary skills to handle hydrogen safely and responsibly.

We offer 3 different courses concerning Power-to-X Safety, Introduction to Hydrogen Safety and Advanced Hydrogen Safety with different levels. All courses are free of charge. Read about the courses here or through the links below and sign up to gain new knowledge and improve your skills within hydrogen technologies.

- Power-to-X Safety: One-day course in Danish

- Introduction to Hydrogen Safety: One-day course in English

- Advanced Hydrogen Safety: Two-day course in English

About DBI -The Danish Institute of Fire and Security Technology

DBI is an independent GTS institute and high-tech research company specialising in fire safety and security. With over 100 years of experience, we offer accredited services in fire prevention, fire technology, and security, aimed at protecting lives and valuables. We work with Danish and international customers in the construction, energy and maritime sectors, ensuring compliance with legislation.

DBI acts as a Danish knowledge centre for fire safety for transport and renewable energy, with competence in risk analysis, testing and simulation. We help customers in energy and transport address new fire risks, improve current safety, and ensure fire safety does not hinder innovation, focusing on Power-to-X, wind energy and container ships. Our interdisciplinary expertise supports product development, consultancy and regulatory integration to meet technical, social and organisational safety needs.

We contribute to Danish and international standardisation, publish industry-related materials, and provide a wide range of fire safety and security courses through our dedicated course department, offering holistic solutions based on specialised knowledge and continuous development.

Danish precision machining specialist CNC Onsite and Dutch blade expert We4Ce have completed their first joint project transferring repair know-how to a wind farm in South Asia. In May, the customer’s technicians were trained to independently repair loose inserts in the root ends of 26 turbine blades. This was the first time the companies' new repair method was put into practice. The method offers a cost-effective and sustainable alternative to full blade replacement by eliminating the need for external transport and potentially reducing blade waste.

CNC Onsite’s specially built precision machine removes the damaged inserts directly on-site, allowing the wind farm’s technicians to apply We4Ce’s patented "Re-FIT" method for mounting and securing new inserts. Prior to the launch of the 50 MW project in South Asia, the technicians were trained in the repair method at We4Ce in the Netherlands and in operation of the precision machine at CNC Onsite in Denmark. The technology is delivered under a licensing model, enabling wind farms to carry out major blade repairs with their own service teams.

Following the training, the customer’s service team in South Asia established a temporary workshop directly in the wind farm, where extensive repairs were carried out over several weeks under the supervision of CNC Onsite and We4Ce.

"Securing and now executing this first contract for our new insert replacement method directly in the wind farm was the result of solid engineering with a focus on practical application," says Arnold Timmer, Managing Director of We4Ce. "We got the idea in early 2022 following a project with a customer in India and then spent three years developing and testing the solution."

By applying the repair technology, the customer will now be able to replace more than 1,000 defective inserts. The process combines precision boring, a specialized fastening method, and installation of replacement inserts, resulting in a component that is nearly as good as new, designed not only for reliable performance but with a projected lifespan of up to 20 years. This process represents a significant improvement over conventional repair methods.

Repair Technology: A Future Opportunity for Operations and Maintenance (O&M)

With operations and maintenance (O&M) being critical to the long-term performance of wind turbines, "remanufacturing" - restoring components to the same or better quality than their original condition - is likely to shape the wind sector’s approach to maintenance in the years to come.

Onsite replacement of blade root inserts is an advanced process requiring the right equipment and components to ensure a strong mechanical connection.

Three industrial work tents, each 100 m² in size, were set up at the wind farm. In the first tent, the blade was bored; in the second, the insert was replaced; and in the third, final finishing and quality checks were carried out.

The We4Ce and CNC Onsite method offers significant advantages: up to 60 percent cost savings, reduced downtime, and environmental benefits by eliminating potential blade waste and the need for transport, which typically involves high logistical costs and CO₂ emissions.

Efficient Boring in Fiberglass Rotor Blades

CNC Onsite designed and built a custom machine for boring out defective inserts from the root ends of turbine blades. The machine produces precisely dimensioned holes tailored to fit the new inserts.

“Boring into fiberglass wears down drill bits quickly, making the process demanding and time-intensive. As part of the project, we developed special drill bits to ensure high precision and efficiency,” explains Søren Kellenberger, Partner and Sales Director at CNC Onsite.

Infusion Technology Ensures Durable Insert Bonding

We4Ce uses its patented infusion technology to securely fasten the replacement inserts. Through an inlet pipe, epoxy resin is injected into the insert while a vacuum ensures even distribution around the cavity.

The insert at the root end of the blade is a safety-critical component that connects the blade to the hub. In certain blades, the insert is embedded in polyester. If the material shrinks or distributes unevenly during manufacturing, microcracks may develop, which over time can lead to larger fractures.

This weakens the bond and increases the risk of insert detachment - potentially causing serious blade damage.

We4Ce and CNC Onsite are currently preparing several upcoming projects with significant potential, including in Brazil and the USA.

About CNC Onsite

Headquartered in Vejle, Denmark, CNC Onsite designs, builds, and delivers high-precision mobile machining equipment for wind turbines, including offshore foundations. The machines can be built for a variety of tasks. CNC Onsite serves the onshore and offshore wind sector, providing solutions such as large-diameter steel flange machining and blade root-end processing; specialized repair services for yaw rings, rotor locks, generator shafts, bearing housings, removal of broken bolts, and thread hole repairs.

www.cnconsite.dk

About We4Ce

Headquartered in Almelo, the Netherlands, We4Ce has more than 25 years of experience in supplying rotor blade technology — both for manufacturing and aftermarket applications. The company specializes in blade design, insert technology for blade roots in sizes M20–M42, and solutions for segmented blades with replaceable root sections.

In the aftermarket, We4Ce performs Root Cause Analyses (RCA) of blade failures and offers a licensing model for its patented Re-FIT remanufacturing method for blade root inserts. In close collaboration with wind farm owners, We4Ce’s research lab conducts fatigue and extreme load testing on various sizes and parameters, supporting the development of inserts for OEMs.

We4Ce also collaborates with TNO’s testing institute for large component trials and certification through bodies such as TÜV and UL.

Media contact

Dr. Malene Conlong

M.conlong@mollerint.dk

+49151 53930015

This text has been translated to English by Energy Cluster Denmark.

CNC Onsite, a Danish mobile machining expert, has delivered its custom-built ”Goliath” machine to wind tower manufacturer Welcon, where it is now milling 97 bottom tower flanges for Vestas’ 15 MW V236 turbines destined for projects in Germany and the Netherlands.Production began last month, April, and the first flanges have already exceeded flatness specifications, ensuring a perfect fit with the transition piece — enhancing reliability and design flexibility and significantly reducing costly post-production checks.

The milling process ensures that the tower and transition piece align perfectly, forming a flat, stable connection between the two flanges, a critical mechanical joint held together with bolts. By implementing CNC Onsite’s machining process, industry leading tolerances are achieved, which eliminates the need for heat straightening, a common post-production step to correct flatness issues, while also optimizing the maintenance of bolts during operation.

The precision machine,”'Goliath”, is a custom-built machine from CNC Onsite, specifically designed to ensure flat flanges for structural strength and fatigue resistance.

Bolted connections with long-term benefits

“On the first flange, we have achieved a global flatness tolerance of 0.21 mm. The required 1 mm for this project is already well below the common industry standard of 2.5 mm, so we are of course very pleased with the machines’ performance," says Soren Kellenberger, Sales Director and Partner at CNC Onsite.

”Ensuring a tolerance of 1 mm or better is a significant benefit when it comes to ensuring correct bolt tightening. With 160 bolts in a flange, reducing maintenance costs and downtime due to loose bolts, is a considerable cost saver."

Welcon will integrate the flange facing process as a standard manufacturing step, replacing the traditional heat straightening method, a controlled heating and cooling process used to correct flatness distortions after welding. By employing Goliath on these 97 bottom flanges, the tower manufacturer can ensure a faster, more uniform method.

Added value for Vestas

The consistent flatness across all flanges will provide Vestas, the customer of Welcon, with greater flexibility in flange designs and dimensions, as well as a broader choice of bolt sizes.

“The industry demand for fine tolerances is increasing. To meet flatness requirements, we need a machine-based process, as heat straightening cannot achieve the necessary precision."

“We also expect this to improve health and safety by eliminating manual work,” says Johnny Hauggaard Skov, Vice Director, Welcon.

“If applied throughout the industry on all flanges, from tower to transition piece, I believe this precision milling will offer a range of benefits. When all flanges are completely flat, it eliminates the costly measurements we have seen both at sea and prior to shipping. It will also provide design freedom, including the option of smaller and even maintenance-free bolts,” says Peter Sigfred Mortensen, Senior Specialist, Offshore Tower Structure, Towers R&D, Vestas.

Meeting new challenges in large-diameter flanges

As wind turbine tower flanges grow in diameter— now reaching 7.5 meters for Vestas' new 15MW turbines, the demand for even finer tolerances increases.

“It is a challenge to achieve the required precision for 4-5-meter diameter flanges. But on today’s seven-plus meter flanges the tolerances are even tighter. This combination of larger diameter and stricter tolerances makes it nearly impossible to meet standards with traditional methods,” says Soren Kellenberger, Sales Director and Partner at CNC Onsite.

Designed for flexibility and speed

Designed for efficient operation, the machine is mounted directly onto the flange. Using adjustable legs with hydraulic cylinders or optional electric actuators, the machine is securely positioned, allowing easy switching between different flange diameters.

Powerful electric motors enable fast, high-precision milling. The machine handles flanges from 6.5 to 10 meters in diameter in the standard configuration and can be adapted for larger sizes. Fully CNC-controlled, the machine can mill flat, tilted, and double-tilted flanges, as well as features like gasket grooves.

Goliath is the result of CNC Onsite’s more than 12 years of expertise in machining flanges for the wind industry. Developed and built based on this extensive experience, the new machine sets new standards for precision and efficiency.

The machine for Welcon is the third custom-built Goliath machine, designed for large diameter flanges, since its launch in 2022. It can be leased or purchased and is currently in use by offshore customers in Denmark and Spain.

About CNC Onsite

Headquartered in Vejle in Denmark, CNC Onsite designs and delivers high precision mobile machining for wind turbines including offshore foundations. Machines built by CNC Onsite are designed to be flexible using its proprietary "building blocks" approach, which means machinery can be built to match a range of tasks. CNC Onsite serves the onshore and offshore wind energy sector delivering as standard solutions: machining of large diameter steel flanges and blade root ends; specialized repair services covering yaw ring, inserts in blade root, rotor lock, generator shaft, bearing housing and threaded holes. Removal and replacement of worn and broken bolts round off the offering.

Website: www.cnconsite.dk

Skibsbyggerivej 5, 3. sal.

9000 Aalborg

Navitas

Inge Lehmanns Gade 10

8000 Aarhus C

House of Offshore Innovation

Kanalen 1

6700 Esbjerg

Port House

Vendersgade 74

7000 Fredericia

BLOXHub

Bloxhub, Bryghusgade 8, 3. sal,

1474 København K

Energy Cluster Denmark

Nørre Havnegade 43

6400 Sønderborg

©Energy Cluster Denmark 2025