New green technology ready to scale: Reversible fuel cell moves from lab to 35 kW prototype

Shiptown is set to take its groundbreaking H-Battery from lab testing to a working prototype in a new innovation project. The technology builds on NASA’s alkaline fuel cell but is free of rare metals—and it can both produce hydrogen and regenerate green electricity.

It’s a reversible fuel cell that can convert excess green electricity into hydrogen—and then back into electricity when, for example, the wind isn’t blowing or the sun isn’t shining.

With Shiptown’s so-called H-Battery, that vision is now one step closer to reality.

The project is supported by the Just Transition Fund via Erhvervsfyrtårn Syd, facilitated by Energy Cluster Denmark, and marks a key milestone toward scaling the technology.

The system combines two core functions in one integrated unit: electrolysis, which turns electricity into hydrogen, and a fuel cell that turns that hydrogen back into electricity. The fuel cell operates at around 60% total efficiency, and the electrolysis process alone reaches over 90%. These numbers place the H-Battery among the most promising solutions for large-scale energy storage.

“You can see it as a complete solution that both stores and delivers green electricity—at industrial scale—helping increase the output of solar and wind farms and balance the electricity grid. What’s unique is that we’ve developed a technology that combines electrolysis and fuel cell in the same unit—without using expensive or rare metals. And thanks to a design optimized for mass production, it’s both more cost-effective and far more scalable,” says Shiptown Co-founder and CEO Marie Vedel Lauridsen.

NASA Tech, Reimagined for Earth

The H-Battery builds on alkaline fuel cell (AFC) technology originally used by NASA in the Apollo program. On Earth, AFCs have been nearly impossible to use because they’re highly sensitive to CO₂ in the air, which reduces performance. But Shiptown has cracked the code—developing a cell that can actively remove CO₂.

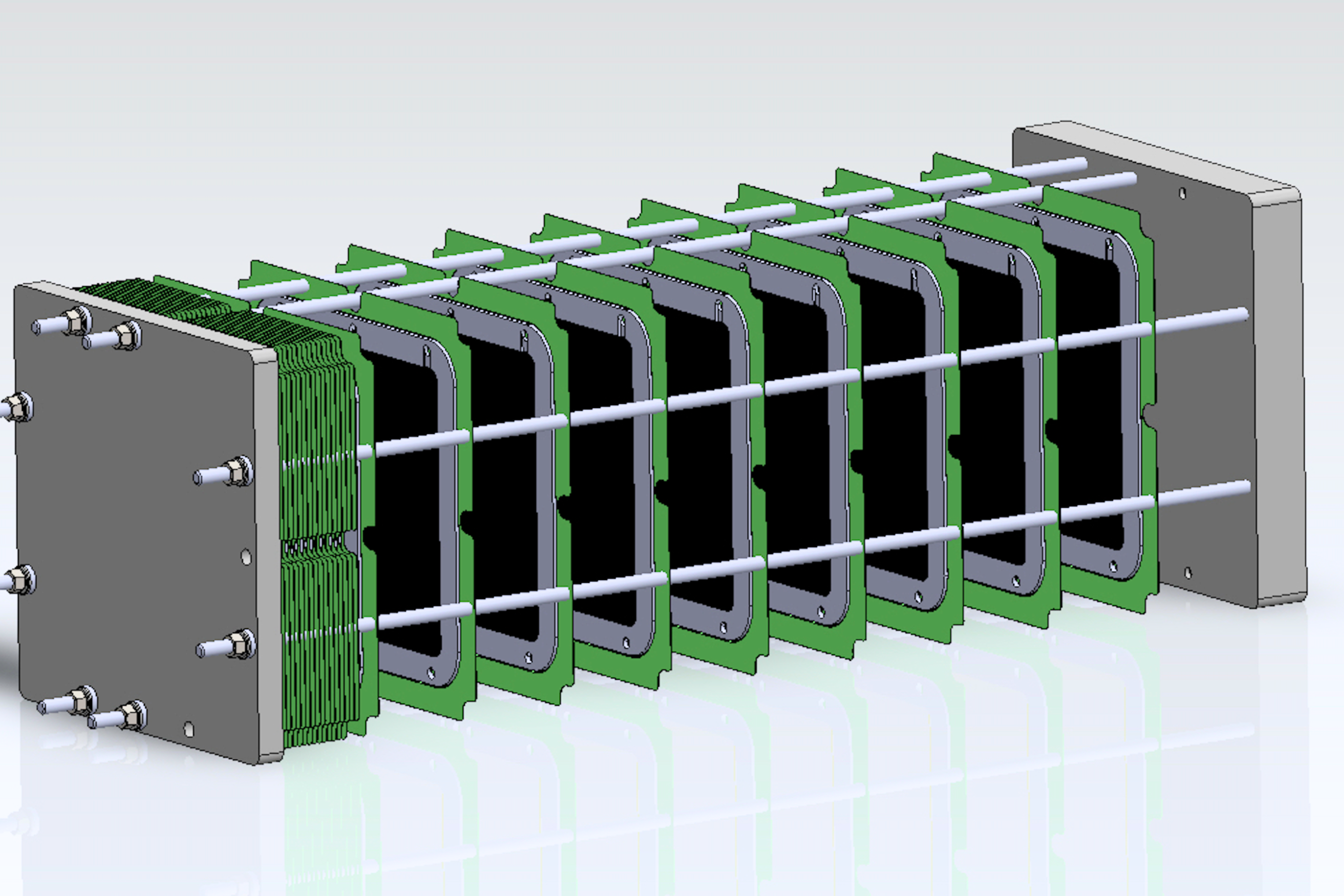

Shiptown has already proven the concept in the lab using a smaller five-cell unit. Now comes the next big leap: developing and testing a 35 kW prototype. The project is being carried out in close collaboration with Nitek ApS, which is handling design and mechanical integration, and Energy Cluster Denmark, which is facilitating the process.

The prototype will be assembled, tested, and prepared for CE certification. The project is expected to run from July 2025 to June 2026 and will lay the groundwork for a future 100 kW unit, as part of a 2 MW full-scale system for use in energy storage, backup solutions, or off-grid applications.

New Funding Builds on Previous Success

This development is based on results from an earlier innovation project—also facilitated by Energy Cluster Denmark—where Shiptown, together with Aarhus University, tested the fuel cell’s CO₂ tolerance and cell structure.

“That first project allowed us, early on, to test CO₂ absorption in the cell in collaboration with Aarhus University. It gave us valuable insights into electrodes, materials, and the potential for CO₂ capture. And with this new funding, we’re now building on those learnings,” says Marie Vedel Lauridsen.

The new grant comes from Erhvervsfyrtårn Syd via the Just Transition Fund (FRO) as part of the BeyondFossil initiative, which supports green solutions with strong potential for industrial scale-up and export.

Latest news

Skibsbyggerivej 5, 3. sal.

9000 Aalborg

Navitas

Inge Lehmanns Gade 10

8000 Aarhus C

House of Offshore Innovation

Kanalen 1

6700 Esbjerg

Port House

Vendersgade 74

7000 Fredericia

BLOXHub

Bloxhub, Bryghusgade 8, 3. sal,

1474 København K

Energy Cluster Denmark

Nørre Havnegade 43

6400 Sønderborg

©Energy Cluster Denmark 2025