New welding technology for repairing cast iron components in wind turbines

Siemens Gamesa, Vestas and other partners have joined forces to solve common challenges in wind turbine maintenance. The result is a new welding method with promising results.

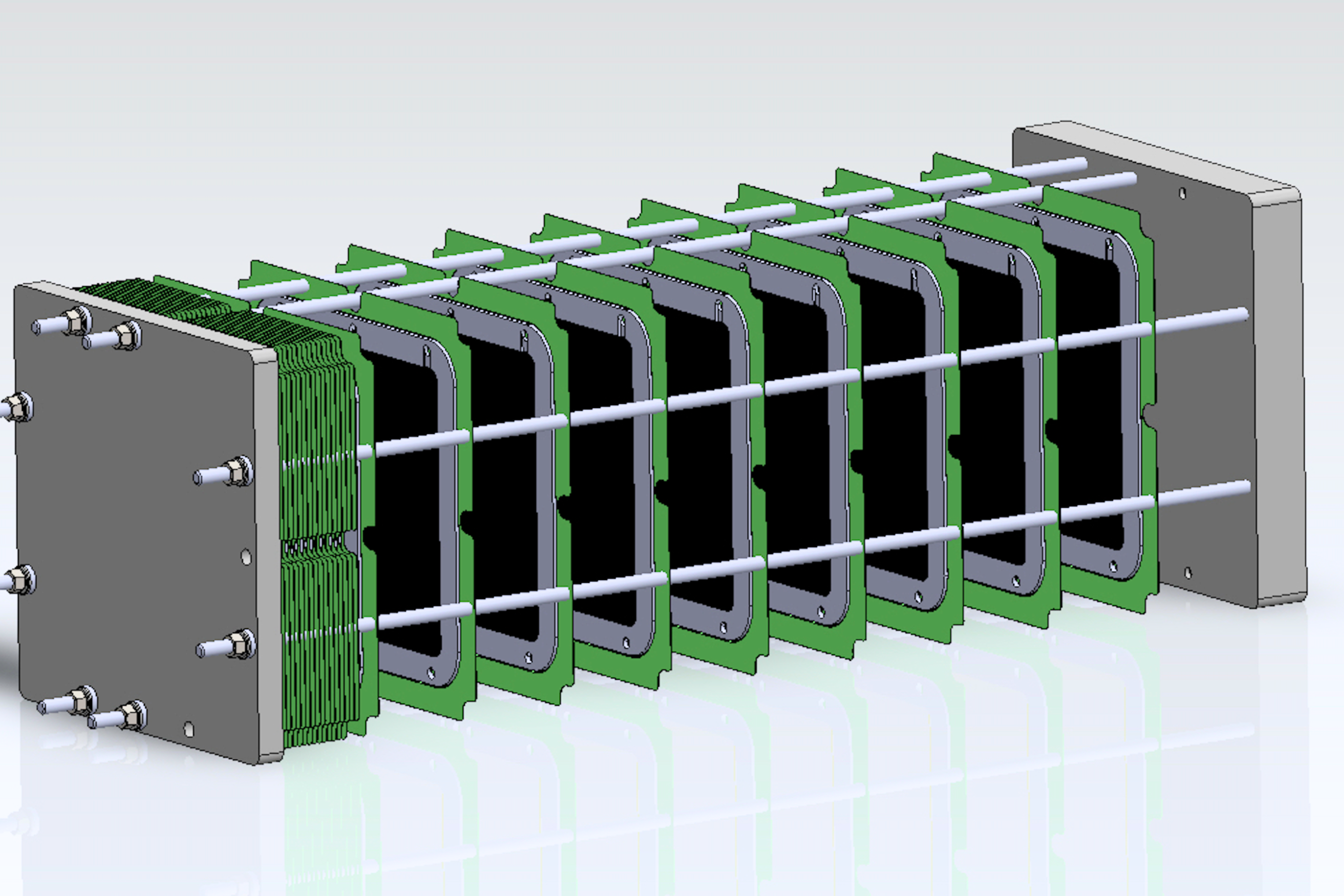

A new welding method enables the repair of large cast iron components in wind turbines.

The technology has the potential to reduce both time, costs and CO2 emissions in the wind energy sector.

The technique is a result of the innovation project WeldCast, which has brought together the partners Siemens Gamesa Renewable Energy, Vestas Wind Systems, FORCE Technology, DTU and Baettr. The project is supported by Innovation Fund Denmark and facilitated by Energy Cluster Denmark.

Common solutions to common challenges

The challenge for the industry is that large cast iron components in wind turbines are not only expensive, but also difficult to repair if defects occur during casting. As a result, many cast parts are discarded.

With increasing turbine sizes, many foundries have difficulty meeting demand, which makes welding an attractive alternative to reduce costs and expand the supplier base.

The innovation project has therefore developed a new welding method that is targeted at repairing defective wind turbine components.

Hans-Frieder Vogt, Team Lead Structural Analysis at Siemens Gamesa, is pleased with the collaboration:

“We have seen that we can discuss details openly without compromising our competitive position and legislation. I believe that the key to good cooperation and joint solutions is that we share many of the same challenges.”

Identify, categorize and repair iron components

The new welding technology simplifies the repair process and reduces both waste and production times.

“We now have a better understanding of how to identify and categorize defects and how to repair them,” says Anders Vedel, Chief Science Advisor at Vestas.

Kaare Jensen, Senior Welding Technician at FORCE Technology, explains:

“We have developed an intermediate layer that adapts to the changes of the weld and fills it with another material, which allows us to make welds without cracks or defects.”

The new technology can lead to more resource-efficient maintenance of turbines, thereby reducing the costs and time spent on repairing large components. Although the results are promising, there is still a lot of work to do before the method can be commercialized.

Looking ahead – a big perspective

If successfully implemented, the technology could change how the wind energy sector handles repairs and potentially reduce the need to scrap large components.

“These solutions allow us to repair indications directly on the production line without having to stop production. This allows us to make quick repairs instead of scrapping,” says Kaare Jensen from FORCE Technology.

Anders Vedel from Vestas says about the future:

“With implementation and rollout, which can hopefully take place in three to four years, we will have something that makes a big and meaningful difference for the entire industry – both for subcontractors and OEMs.”

Facts about WeldCast

The WeldCast project started in 2021 with partners from Siemens Gamesa Renewable Energy A/S, Vestas Wind Systems, BEATTR, FORCE Technology, DTU – Technical University of Denmark and Energy Cluster Denmark. The project is funded by Innovation Fund Denmark.

Want to know more about WeldCast? Contact Christian Boysen, COO, Energy Cluster Denmark: +45 61 71 86 63 / chb@energycluster.dk.

Read more about WeldCast or watch the project video here: https://www.energycluster.dk/en/projects/weldcast/

Latest news

Skibsbyggerivej 5, 3. sal.

9000 Aalborg

Navitas

Inge Lehmanns Gade 10

8000 Aarhus C

House of Offshore Innovation

Kanalen 1

6700 Esbjerg

Port House

Vendersgade 74

7000 Fredericia

BLOXHub

Bloxhub, Bryghusgade 8, 3. sal,

1474 København K

Energy Cluster Denmark

Nørre Havnegade 43

6400 Sønderborg

©Energy Cluster Denmark 2025